This time, we’re going to talk about What Are Cinder Blocks Made Of. There is a lot of information about Concrete Block Deutsch on the internet, of course. Social media are getting better and better quickly, which makes it easier for us to learn new things.

Cinder Block Vs. Concrete Block and Fly Ash Cement are also linked to information about Building Block. As for other things that need to be looked up, they are about Autoclaved Aerated Concrete and have something to do with Concrete Blocks - Manufacturing, Classification & Uses.

68 Tips for What Are Cinder Blocks Made Of | what are concrete blocks made of

- When you burn coal or wood, it leaves behind a residue we call ash or cinders. To make cinder blocks, you combine these cinders with cement. The result is a lightweight, hollow and sturdy block. - Source: Internet

- They should be manufactured for specific concrete strength of 4.0 and 5.0 N/mm² in 28 days. These blocks are used as load-bearing walls and have a density of not less than 1800 kg/m³. - Source: Internet

- Coal cinder blocks are light-weight, low density concrete masonry units (CMUs). They are made from Portland cement and an aggregate of burned coal cinders. The mixture is poured into molds and then heated or air dried. Traditionally, coal cinder blocks have either two or three hollow interior areas. - Source: Internet

- Standard, plain hollow concrete blocks start at about $1.00 each. Some fancier ones range up to $4.00 each. - Source: Internet

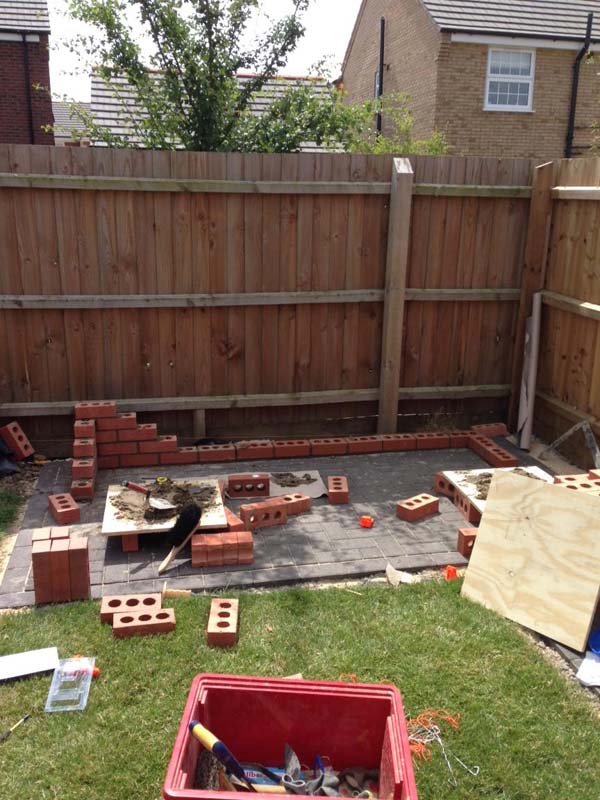

- One of the many benefits of using cement blocks is that they stack so nicely. You can grow your vegetables in raised beds. Raising your beds helps with water drainage and – your back. - Source: Internet

- To produce the concrete blocks based on your market demand and local availabilities you need to choose the right machine and a suitable concrete block manufacturing business plan. Bess engineers can help you in every step of this business. All you need to do is to contact us. - Source: Internet

- Don’t like the look of cinder blocks? Try cementing shells, pebbles or cut glass to the outside. Paint striking modern designs or use stencils. Contrast the light grey cinder block with other materials like rough wood, dark wood, slate, or terracotta. - Source: Internet

- To lay the first course of blocks, use a trowel to spread out a full bed of mortar about 1.25cm thick on the footing. To prevent the mortar from drying out before blocks are laid in it, spread only enough for 4 or 5 blocks at a time. - Source: Internet

- In the semi-automatic concrete block manufacturing process you need a machine that produces the blocks. This machine is called a concrete block machine, it has molds installed in it and produces concrete blocks using pressure and vibration in the molds. The advantages of the semi-automatic concrete block manufacturing process are that your final product quality is higher than manual since it is produced using hydraulic pressure and vibration. - Source: Internet

- Sand-cement blocks may be molded by hand or with a simple hand-press. Blocks made by press are generally stronger and more durable. But blocks made by either method are acceptable. - Source: Internet

- Sand-cement blocks should be sprinkled with water after they have set for about 12 hours. They should be dampened at least once a day for 5 days. They should not be laid up in a wall for at least 12 days after being molded. - Source: Internet

- In this article, we will talk about cinder block vs. concrete block that are two different structural elements confused with each other. Although their major elements are same, these two structural elements have very different properties. - Source: Internet

- Next, lay out the planned number of blocks for the first row (course) on or alongside the footing and check to see how well they fit the length of the wall. Very small adjustments in the length of a wall (under 7.5cm over the length of the whole wall) may be made by increasing the size of mortar joints between every 5th or 6th block. For example, if 8 joints are made 1cm instead of ˝cm the wall length will be increased 4cm without cutting any blocks. - Source: Internet

- Cinder blocks have a long, proud history in the American building industry. In the late eighteenth century, coal-burning factories dominated the industrial landscape of the US. All that coal produced huge quantities of cinders that people turned into cinder blocks. - Source: Internet

- The manual method is the simplest and cheapest way. All you need is molds. The concrete is mixed manually and then poured into the concrete block molds. Usually, there is no vibration and high pressure in the manual method so the quality of the concrete blocks is low. - Source: Internet

- Any excess mortar that squeezes out between blocks should be scraped off. It can be re-used if it has not dried out. Once mortar dries out it must be discarded. - Source: Internet

- Molding With A Hand Press. There are several types of hand press available for making strong sandcement blocks. Cinva-Ram and TekBlock presses are the most common, but any similar press will work as well. - Source: Internet

- Cinder blocks are great for building fire pits. Concrete is a non-flammable material. In fact, a cinder block fire wall will absorb heat and protect you from sparks. - Source: Internet

- Some construction projects call for a larger masonry block than a standard brick, but solid concrete blocks can be very expensive and very heavy. One common compromise are largely hollow masonry blocks known as cinder blocks. These are also sometimes referred to as concrete blocks, breeze blocks, or concrete masonry units (CMUs), though these terms have nuanced differences among them. Cinder blocks are generally lighter than solid concrete blocks, which makes them easier for brick masons to place in position. The hollow spaces in the blocks also provide some natural insulation or allow grout to be poured inside the rows of masonry. - Source: Internet

- Nope, not your car. Yeah, sure, we’ve all seen it done lots of times. But what you may not see is when the cinder block fails and the car crashes to the ground – not something you want to risk, particularly if you are working underneath it. - Source: Internet

- Because cinder blocks do not have a significant amount of tensile strength, concrete is often poured vertically into the hollow chambers to provide more stability and strength. An metal rod called rebar is often placed vertically in the hollow chambers as well to reinforce the poured grout and the wall in general. It is not unusual to see rows of blocks with lengths of exposed rebar on construction sites. - Source: Internet

- Hand Molding. If a commercially made mold is not available, a mold’ can be made out of 2.5-5cm lumber in the dimensions desired. Typically, these blocks are: - Source: Internet

- Depending on the application of the block, the hollow area may be manipulated. For example, one may decide to divide a hollow concrete block into components or make slight adjustments in the shape of the void area. Let’s have a look at the variations of hollow concrete blocks. - Source: Internet

- In the early years of the 20th century as concrete masonry units were beginning to be used with more frequency, producers were looking for ways to reduce the weight of the units to facilitate their use in construction and increase mason productivity. To reduce the unit weight, many producers (but not all) incorporated cinders into their block as an alternative to conventional stone aggregate. Cinders, which include both waste by-products of coal combustion as well as volcanic cinders, were an ideal, cost- effective, lightweight aggregate that was readily available in many areas of the country. Soon after, the terms “cinder” and “block” were perpetually linked. The use of waste by-products such as coal cinders effectively made concrete masonry the first construction material to adopt green, sustainable practices; a century before it was fashionable to do so. - Source: Internet

- What’s the difference between concrete blocks and coal cinder blocks? It’s the aggregate. A hollow concrete block is made of two things – an aggregate and Portland cement. For concrete blocks, the aggregate is made of sand and small pebbles. For coal cinder blocks, the aggregate is coal cinder. - Source: Internet

- For hollow concrete blocks, there is also a small chance of lime contamination. Sealants would take care of that. The cells are a perfect size for single plants and the cement won’t ever rot, like wood. - Source: Internet

- Today, you don’t see that many homes in the US are made from cinder blocks or concrete. Concrete and cinder blocks are popular in places like Florida because they can withstand hurricanes. They’re also common building materials in Europe, Latin American and the Caribbean. - Source: Internet

- Actual sizes will be less than 10 mm of mortar thickness. For Concrete and Hollow concrete blocks nominal length 390 mm and height 190 mm. The thickness for loadbearing walls is 190 mm, compound walls 140 mm and for filler walls 90 mm. - Source: Internet

- In 1900, Harmon S. Palmer invented the first machine that could produce large quantities of cinder blocks. This coupled with growing industry in Portland cement to make cinder blocks one of the chief building materials in the country. - Source: Internet

- As for spray painting concrete blocks, please go ahead. On cinder blocks, spray paint is definitely an option. It can be applied without any problems. Especially so, if the spray paint was intended for outside use, it should continue to be completely visible. - Source: Internet

- A: Concrete walls block WiFi signals if they’re poured solid or left as hollow blocks. The thicker the wall, the harder it is for a signal to pass through. Especially if the wall contains steel reinforcement like horizontal and vertical rebar. - Source: Internet

- A: There are many different names for the concrete blocks in parking lots. Depending on the maker and location, they go by a variety of names. These include parking blocks, parking stops, and curb stops. - Source: Internet

- We checked loads of gardening websites to see if people had bad experiences. We didn’t find any. Lots of people use cinder blocks to grow vegetables, plants and flowers. - Source: Internet

- The practice of incorporating coal combustion cinders (as well as other waste by-products) into concrete masonry units continues today. Yet, using cinder aggregates as a lightweight alternative to stone and gravel aggregate may have inadvertently led to another common misconception regarding the term cinder block: that cinder block are lighter (have a lower density) compared to concrete masonry units. While it is true that a concrete block manufactured with cinders will tend to have a lower density compared to a concrete block manufactured with stone aggregate, there are many other lightweight aggregate types (both natural and man-made) that are commonly used in block production. As such, the density of a block is not an indication of whether it has been manufactured with or without cinders. - Source: Internet

- then, the casing. Repeat the process until enough blocks have been made. Using several molds simultaneously will greatly speed the process. - Source: Internet

- Concrete typically doesn’t need additional fire protection due to its inherent fire resistance. It is a non-combustible substance that it transfers heat slowly and doesn’t burn. In this aspect, are cement blocks fireproof? - Source: Internet

- Cinder blocks are ideal for stacking. Experts say that cinder blocks shouldn’t be free stacked higher than 6 feet, 8 inches. If you want to construct something hide and wide, consider adding some rebar both horizontally and vertically. - Source: Internet

- Coal cinder blocks are not strong enough for load bearing walls. Hollow concrete block walls are. Experts say to reinforce your hollow concrete wall with rebar and cement inside the cells. - Source: Internet

- BIS recommends a fineness modulus of the combined aggregate between 3.6 to 4 and coarse aggregates used are of size 6 to 12 mm. Lean mixes up to 1:8 are generally used. Concrete mix for concrete blocks should not be richer than one part of the cement to six parts of the volume of combined aggregate. - Source: Internet

- Cinder blocks are made from ash and cinders while concrete blocks are made from steel and cement. As a result, cinder blocks are hollow and lightweight. The concrete block is heavy and durable. - Source: Internet

- If you are shopping for hollow concrete blocks, see if you can find some that are fire rated. The blocks shouldn’t be sealed. Concrete blocks are porous – and that’s a good thing for a fire pit. The fire pit blocks will get wet – in the rain or with the hose – and water will get inside the pores. - Source: Internet

- Concrete bricks and blocks can easily be made at home with only a few items. Making your own concrete bricks and blocks can save you money if you are looking to build a small structure at home. You can even start your own small business producing these cost-effective building materials. - Source: Internet

- The moisture in stabilized earth blocks should be eliminated slowly, under cover, with the blocks protected from sun and rain. For the first 3-4 days the blocks should be separated in single rows, never stacked upon each other. They should be sprinkled lightly with water twice a day for this initial period. After 4 days, the blocks may be stacked up to 10 layers high in a pyramid fashion with a little space between each brick. On the 8th day, bricks may be laid up in a wall where they will continue to cure and gain full strength in about 30 days. - Source: Internet

- What is a traditional cinder block? Cinder is actually what it sounds like – a small piece of something that burned. In the case of cinder blocks, the thing that’s burned is coal. The coal cinders are leftover products from coal-burning power plants – the fly and bottom ash portions. - Source: Internet

- Lintel blocks, also known as channeled blocks, are U-shaped concrete masonry units. They are primarily used in the preparation of lintel beams. Attached on top of windows and doors, lintel blocks bear the load coming from the top of the structure. - Source: Internet

- A: Yes. Using construction adhesive, you can join two concrete blocks together. This substance is thick paste created by combining cement, water, and sand. - Source: Internet

- Cinder is a generic name for ash. In ancient times, people used to burn coal. Fly ash is left behind when coal or similar fuels are burned. This fly ash is used to manufacture cinder blocks. - Source: Internet

- Coal cinder blocks are ideal for small scale garden and home projects. Coal cinder blocks should not be used for anything load-bearing. Check your building codes if you are planning to build an entire structure with them, because they might not be strong enough. - Source: Internet

- Concrete Masonry Units or CMU are known as hollow concrete blocks, concrete bricks or concrete masonry. Concrete blocks are composed of Portland cement and aggregate, the high density blocks may use sand and gravel while low density blocks use industrial waste instead of aggregate. Lightweight blocks are made using aerated concrete.The hollow concrete blocks are manufactured , hardened and cured before reaching the site and is a very durable and strong material. - Source: Internet

- Depending on your country you can use different aggregates as well, most common aggregates are limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore. You can read more about this topic in Concrete Network. You can also read more about hollow concrete blocks in our article ‘‘what hollow concrete block is in general and in detail’’. - Source: Internet

- Cinder and concrete blocks can be heavy and difficult to handle. It’s also difficult to mortar them correctly. If you want a cinder block construction, contact a professional masonry company for safe, expert installation. Capital Masonry is a third-generation, award-winning masonry company that specializes in all types of stone and concrete installation. - Source: Internet

- Construction of a block foundation wall requires 3 basic steps: . Making the blocks; . Laying the blocks; . Finishing the Mortar. - Source: Internet

- A concrete block is a block made of concrete. To raise the quality of the blocks you need to apply vibration and force to make the mortar as compressed as possible. A concrete block is a general name and includes different types of blocks. Below you can see some examples of concrete blocks. - Source: Internet

- Keep aggregates and cement dry and separate until you need to mix them. Ideally, bags of cement should be stored in a dry room. You’ll need space to produce and store the concrete bricks and blocks. A flat concrete slab will be perfect. You will be able to store 1000 bricks or 200 blocks for curing and drying on a space of about 50 square metres. - Source: Internet

- Cinder block vs concrete block comparison may not be understood at first glance. Although the same materials are used in the construction of the two, there is an extra material in the cinder block. It is included in the composition to perform various functions. - Source: Internet

- The best sand is clean river-bed sand composed of many different size particles. If it is dirty, the sand should be washed, or sifted through a fine screen (4-5mm square), since dirt will weaken the blocks. Do not use ocean sand. - Source: Internet

- Unlike a stretcher concrete block or corner block, a concrete pillar blocks is designed in a way that both its ends are visible. This is why these concrete block types are also known as double corner blocks. Concrete pillar blocks are most commonly used in building pillars or piers. - Source: Internet

- The soil should shrink and develop 3 or 4 cracks. If 6 or more cracks appear, or if the dried soil arches out of the box, reject the soil. It will not make good blocks. As long as there are less than 6 cracks and the soil lies flat in the box, measure the shrinkage by tapping the box and sliding the soil to one end: - Source: Internet

- The best natural soil for stabilized earth blocks is sandy clay. As with plain concrete, the strongest blocks have a combination of fine, medium, and coarse particles. Earth that has only one particle size, or has mostly organic and/or coarse particles is unacceptable. - Source: Internet

- To produce concrete blocks you need to provide your plant with raw materials like aggregate, water, and portland cement. Then you need to mix them together to have a homogenous creamy mixture. There are different mixture ratios available based on your country’s standards and aggregate availability. Also based on your machine choice it is done manually or automatically. - Source: Internet

- When bricklayers work with cinder blocks, they generally use techniques similar to standard brick laying. The alternative rows of blocks are carefully offset so that the second layer stabilizes the first. A line of mortar is put down between each layer, so the actual dimensions of a standard cinder block may be adjusted slightly to accommodate the mortar. Corners may be finished out with half blocks, or interlaced to create a four-cornered structure. - Source: Internet

- What has changed over the past 100 years is the technology used today to produce concrete masonry results in a consistently high-quality product with uniform properties. Likewise, codes and standards have evolved through the years to comprehensively address minimum physical requirements for concrete masonry to ensure the long-term durability and performance of these products. Consequently, some associate cinder block with inconsistent or poor quality units produced in early 20th century, which has led some to believe that cinder block are not permitted to be used to construct buildings today. The reality is that all concrete masonry units used in construction must meet minimum requirements established by building codes, regardless of whether they contain cinders or not. Further, regardless of whether you are studying a newly constructed building or a 100 year old foundation – those concrete units are concrete masonry units, CMU, concrete block…or if you prefer, cinder block – although it is nearly impossible to tell visually if a given unit contains actual cinders. - Source: Internet

- Depending on the concrete block you are producing, the capacity of your concrete block manufacturing plant is different. Usually, paving block production capacity is discussed in square meters and the hollow blocks and solid blocks are described in numbers. The concrete block machines offered by Bess can produce 4000 pieces of standard blocks (20cm width x 40cm length x 20cm height) or 300 square meters of paving blocks in eight hours. - Source: Internet

- Cinder blocks are made of concrete and coal cinders. In cinder blocks instead of sand or gravel, much of the aggregate filling material is coal cinder. These types of blocks are lighter than conventional concrete blocks. The strength of the cinder block is less compared to the concrete block. - Source: Internet

- Cinder blocks differ from concrete blocks in other ways besides their hollow design. Concrete blocks are made from a slurry of Portland cement and small aggregate, such as small stones or gravel. This makes them heavier and smoother than cinder blocks, which are made from a combination of Portland cement and cinders, the dusty remnants of burned coal. - Source: Internet

- But the truth is, the terms concrete block and cinder block have become synonymous. Many stores have hollow, cored or celled blocks made of concrete that are labeled “cinder block”. Check the fine print – your cinder block may not have been made with coal cinder. More likely, it’s concrete. - Source: Internet

- Absolutely. Consider a coat of sealant or primer first because cinder blocks are super porous. Then, use exterior paints, either spray paints or liquid paints. - Source: Internet

- Concrete blocks have a wide range of uses. They are commonly used as partition blocks, and in retaining walls in both residential and commercial contexts. They also serve as security barriers, and are often lined up on roads to control the flow of foot traffic at any given event. - Source: Internet

Here are a few tips to help you find information about Cinder Block - Deutsch:

- Look for good places to get information about Concrete Block Deutsch. This can be done in libraries, on websites, or even by paid journalists.

- When looking for information about what are lightweight concrete blocks made of, it’s important to know that there are different kinds of online sources, like Google and YouTube. Social media sites like Facebook and Twitter are also good places to look for information about Masonry Block.

Video | What Are Cinder Blocks Made Of

To get the best information about Concrete Blocks Material Mixture Ratio Pdf, you should read to find out how true each source is.

This article has a few videos from different places about Concrete Blocks Material Mixture Ratio Pdf that will help you learn more about it. The Internet is a great place to find out about a wide range of things.

## Here are some crucial aspects concerning Cinder Blocks (15 Things You Always Wanted To Know):- What Are Cinder Blocks Made Of

- How Are Cinder Blocks Made

- What Are Concrete Blocks Made Of

- What Are Cement Blocks Made Of

- What Are Concrete Blocks Made Out Of

With so many websites and forums that talk about Cinder Block, it shouldn’t be hard to find what you need.

Most people are used to getting information about Cinder Block Vs Concrete Block in a very different way than this. It lets you look at the information about Cinder Block Vs Concrete Wall and how it can be used in more detail.

ways to put information about Are Cinder Blocks Still Made in a way that looks good and is useful. They can be used in business and marketing, and they can also be used to talk about What are Cinder Blocks?. So, we also give you some pictures about Concrete Blocks Material Mixture Ratio Pdf.

ways to put information about Are Cinder Blocks Still Made in a way that looks good and is useful. They can be used in business and marketing, and they can also be used to talk about What are Cinder Blocks?. So, we also give you some pictures about Concrete Blocks Material Mixture Ratio Pdf.

In the end, this article gives a summary of Cinder Block Vs Concrete Block | What Is Cinder Blocks | What Is Concrete Blocks. Also talked about are Composition Of Concrete Blocks and When Were Cinder Blocks First Used For Foundations, which you can use to compare how much you know about Concrete Block Manufacturing Process.